Turn car wiring harness into Lego bricks? Tesla announces patent for new harness

As the main body of the automobile circuit network, the automobile wiring harness is responsible for connecting the automobile electrical equipment and making it work normally. However, as the functions of automobiles increase, more and more electrical equipment places a heavy burden on the wiring harness. At present, the total length of the automotive wiring harness has reached several kilometers, which has largely tested the layout and performance of the automotive wiring harness in the layout process. However, flexible wiring harnesses are difficult to install with automated equipment and have become a relatively time-consuming part of the production line.

All along, Tesla has been working to reduce the length of the harness. From the Model S ’s 3km long harness to the Model 3 ’s 1.5km harness, a significant technological breakthrough has been made. However, at the production level, the reduced length of the harness has not brought much change to the production form, and it still requires manual assembly. However, Tesla's recently submitted patent shows a new type of modular wiring harness, which effectively solves the above problems.

Harness length is only one-fifth of Model 3

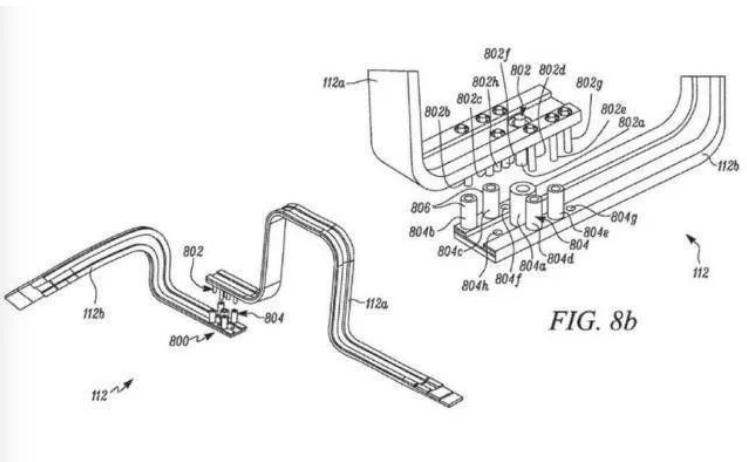

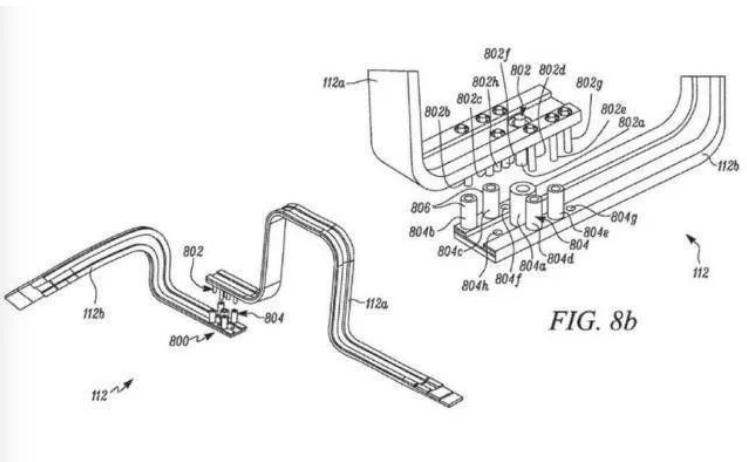

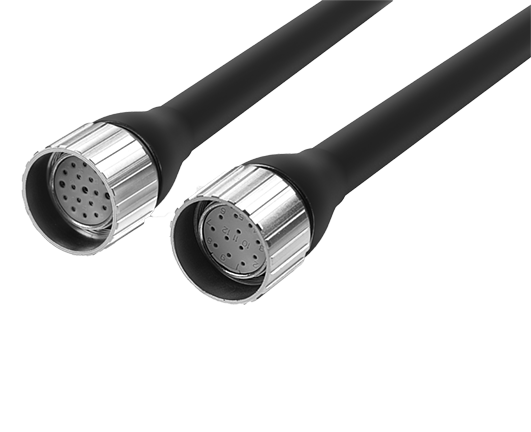

Tesla's new modular wiring harness patent upgrades the existing soft wiring harness to integrate with a hard material frame. After the rigidity of the wiring harness is increased, it is easier to be picked up, moved and installed by the mechanical arm.

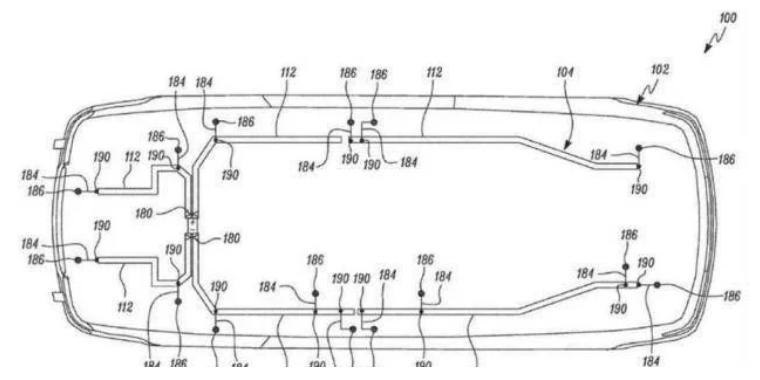

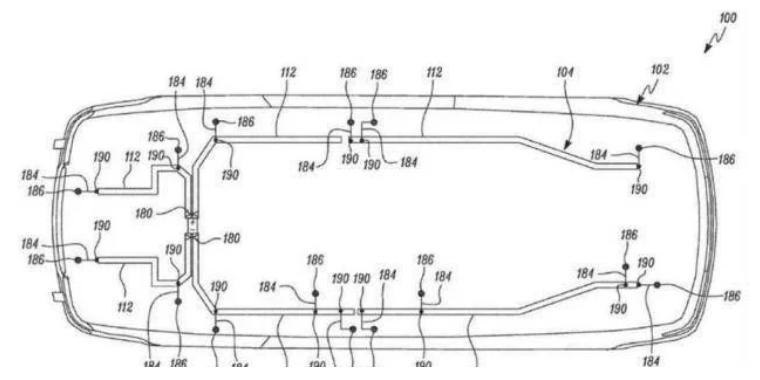

According to the picture effect of the patent picture, the integrated shell of the wiring harness has a certain bending ability, which can better adapt to the structural changes in the car. The wiring harness within each integration has also become more, hoping to reduce the total length in this more efficient integration.

Musk said that Model Y, which will be mass-produced, will be the first to apply the new modular harness, hoping that the total length of the harness will not exceed 100 meters. This number is only one-fifth of the Model 3 on the same platform.

Plug-in connection facilitates automated installation

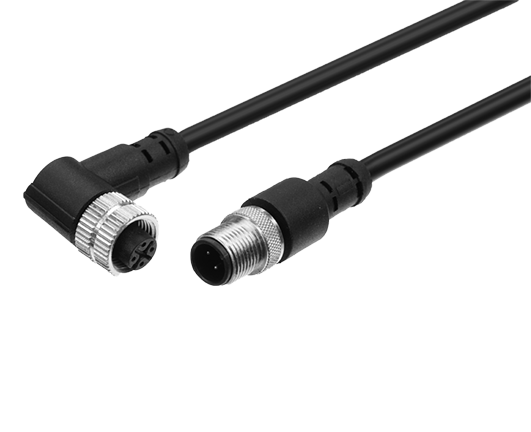

In terms of installation method, the new modular wiring harness also gave up the connection method of the flexible wiring harness winding wiring, but set up the door assembly and sub-components at both ends of the wiring harness, thus having a plug-in splicing effect similar to Lego blocks. This form provides tremendous help for the automation process, and the robot to complete the connection of the modular harness will become a reality.

However, the operating conditions of automobiles are full of variability, which has a severe test on the ability of the internal structure of the vehicle to resist impact and aging. Whether the hard connection installation method of Tesla's new wiring harness can meet the complex conditions facing the car, ensure performance and safety during the service life, and whether the aging of the material affects the stability of the connection and the misalignment caused by vibration. Is a question to be verified.

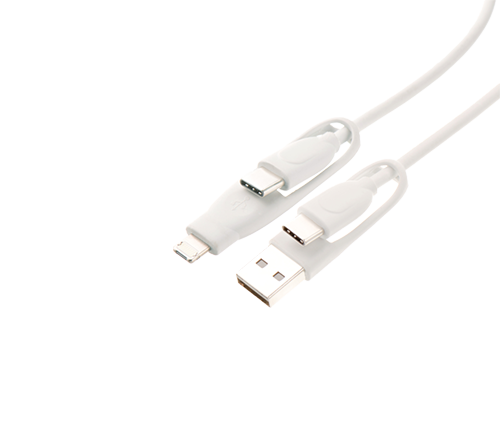

Replace rectangular cross-section wire

Tesla also believes that circular cross-section conductors are not suitable for transmitting current. In the new wire harness, a rectangular cross-section conductor is used. In addition, under the same cross-sectional area, the height of the rectangular cross-section conductor is smaller than that of the ci

Related Products

Related Products

View More(Total0)Comment Lists