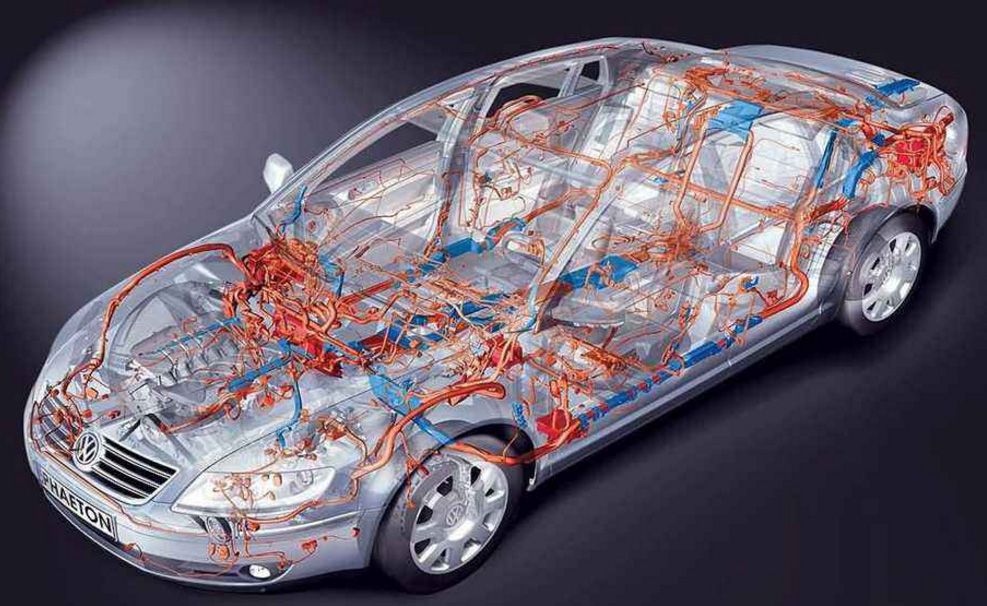

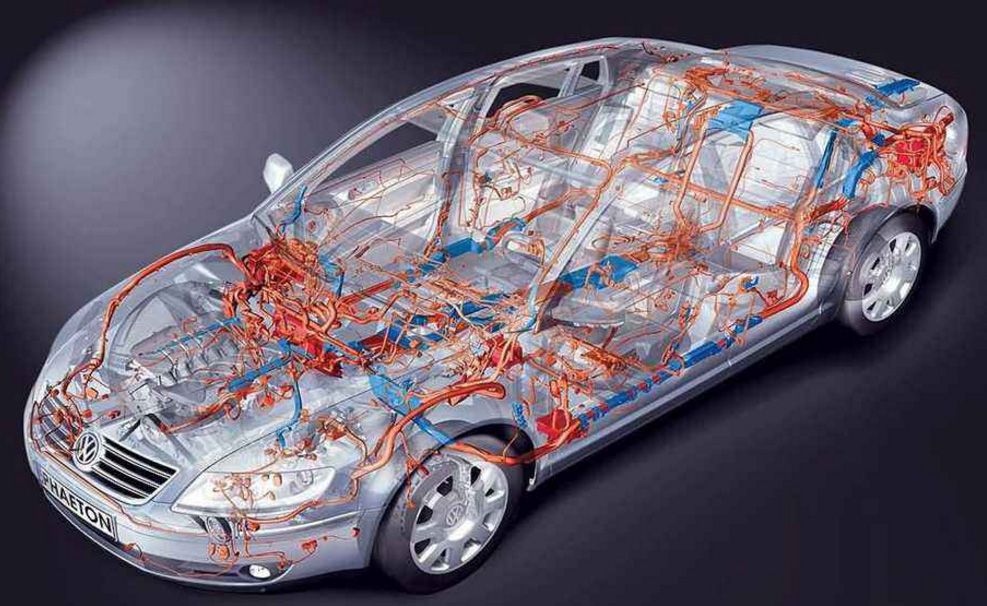

Points for attention in the process design and development of Automobile Wiring Harness

Stripping length

When crimping all terminals for the first time, a reasonable stripping length must be set to avoid the crimping not in place and the core wire exposed too long.

The design of the stripping length is set according to the actual structure size of the terminal, and sometimes it is necessary to consider whether the exposed core wire has an effect on the matching needle seat.

Cutting length and finished length

The setting of tangent length should be based on actual production, and the tolerance of tangent length and finished product length should be paid attention to.

In the process documents, the general length tolerance is explained. When the length of the finished product exceeds 1000mm, the positive tolerance of the finished product length should be set according to 1% of 1000±10. When the length of the finished product is 50000, the tolerance should be set It is set as: +500/-100, and the tolerance of the tangent length needs to be adjusted appropriately. It cannot be set as ±2 regardless of the length.

Tail treatment

Wire tail treatment can be divided into: tin enamel, twist enamel, half-stripped, and other special treatments (such as tail bending).

After customer tail processing, there are two possibilities for use:

1. Directly insert into the PCB hole, at this time there are requirements for the OD after tinning; the PCB board size needs to be determined;

2. It may be welded with other components. At this time, the OD requirements after enamel can be appropriately relaxed.

Before drawing, if the tail is stripped and tinned, you must confirm the following three points with the customer:

①Which way is the customer tail? Insert it directly into the PCB hole, or solder with other components?

②If it is directly inserted into the PCB board hole, what is the specific size of the PCB board hole? This determines whether or not twisting is required.

③In principle, stripping heads below 3mm is not conducive to half-stripping, so it is generally not twisted. When handling this type of tail stripping, you need to confirm with the customer the OD size of the core wire after tinning the tail. If there is no requirement for the OD size after enamelling, please mark the enamelling size on the drawing directly according to the required tail immersion tin standard.

Shielded wire processing method

1. Refer to "Technical Standards for Shielded Wire Trimming" for the processing method of shielded wire for regular customers.

2. When the shielding layer structure of the shielded wire exceeds the terminal crimping range, the shielding layer needs to be trimmed. When trimming, the largest wire standard for terminal crimping should be used.

3. The shielded wire with aluminum foil cannot be boiled to shrink.

Wire processing method

1. If the customer has no special requirements, if the length of the finished product is less than 100mm, the length of the split line should be controlled within 20±5m, and if the length of the finished product is more than 100mm, the length of the split line should be controlled within 30±5mm.

2. UL2651 TS wire, UL20080 flexible cable, the tail is not suitable for twisting and tinning operation, because the PVC insulation layer of UL2651 and UL20080 wire is not completely circular with the copper wire, and it is not easy to perform semi-stripping and retaining operation. Therefore, it is not suitable for twisting and tinning work; if the customer needs to insert the PCB board at the tail, it is recommended to use UL2468 UL2651 TC wire.

3. Spacing TC cable, after peeling off the tail, it can replace SAN, SCN and other pointed terminals.

LVDS wire cutting length setting method

Because LVDS lines generally use small-pitch, multi-P-position plastic cases, the hanging neck phenomenon needs to be considered when designing the tangent length of the scattered line.

Precautions for double-row plastic shell design

1. When selecting wires, try to use flat wires;

2. If the customer must use a single line, try to design different colors to facilitate assembly;

3. The drawing of the double-row plastic shell needs a unified format;

4. When drawing, please pay attention to the arrangement method of the double-row plastic shell feet provided by the customer. Confirm the arrangement method with the customer first to avoid the phenomenon of incompatible feet (especially DuPont type double-row).

Precautions when designing circuit board terminals

1. Circuit board terminals refer to terminals, tube-shaped terminals, pin-shaped terminals, etc. that are directly inserted into the PCB board;

2. When designing the drawing of the circuit board terminal, it is necessary to confirm the size of the PCB board with the customer;

3. When designing drawings of circuit board terminals, the crimping width after crimping must be marked. This width is not only related to the aperture size of the terminal suitable for the PCB board, but also related to the actual PCB board aperture of the customer, so before drawing, please contact the customer first to confirm the size of the PCB board aperture and mark it on the drawing;

4. When designing this kind of terminal, it is necessary to confirm with the customer whether there is a requirement for its shape? Some samples are provided by the customer, and you need to confirm with the customer whether the shape after crimping is the same as the customer's.

Cautions for the design of clamp terminals

The clamp terminals in the same position should be staggered by more than 20mm to prevent mutual short circuit.

Precautions for terminal crimping design

The terminal is matched with the wire. Generally, it needs to be set according to the crimping range of the terminal. Pay attention to the outer diameter of the wire insulation for the terminal.

When the terminal selection exceeds the standard, there are four solutions:

1. Change the terminal model and choose a terminal with a suitable wire specification;

2. Change the wire specifications to suit the crimping range of the terminal;

3. If the wire is too small, the core wire can be folded in half before crimping, and the processing cost is high;

4. When the wire is too large, the insulation rubber can be removed and the heat shrinkable tube can be wrapped after crimping

Any of the above schemes must be confirmed with the customer.

The terminal profile is carried out under the following conditions:

1. When requested by customers;

2. When selecting new terminals;

3. After the new knife mold is made;

4. High current terminal;

5. All terminals on automobile wiring harness;

6. Other special terminals.

The judgment standard of the profile generally refers to the company's internal standard (AMP standard). When customers have different standards, they need to discuss the hidden dangers that may be caused by standard differences.

Pay attention to when designing:

1. The selection of rubber material meets the requirements of customers' products (such as temperature resistance, wear resistance, corrosion resistance, etc.);

2. The size of injection molded parts must be provided by the customer, or provide samples;

3. Dimension control after injection molding;

4. Selection of injection molding machine;

5. Process control of injection molded parts (such as the ratio of new material to recycled material, the ratio of color masterbatch, baking time, molding temperature, cooling time, etc.).

Precautions for handling technical document change notices

Note the following points for ECN changes:

1. There are complete and clear ECR requirements (including change method, order number, material survey).

2. ERP "in use" needs to be removed from the drawing immediately, and the reason for the change, date, and ID number should be indicated in the remarks. When "in use" is turned on, in principle, it needs to be opened by the person who deactivates or needs to contact the person who deactivates Turn it on after confirming the details.

3. For the ECR that is changed immediately, the drawings and ECN must be issued to the workshop within 2 hours.

4. The implementation date of ECN should be written in accordance with the requirements on ECR, instead of simply writing "natural change" or "immediate change".

View More(Total0)Comment Lists