Laser optical cable is a component that uses quartz fiber as the main medium to transmit laser energy. Together with the laser light source and the laser processing head, it constitutes the three most basic parts of the laser. At present, it is mainly used for laser energy transmission of continuous or long pulse laser (ms pulse width) such as infrared laser and green light. As shown in the figure below, the laser optical cable is mainly composed of optical fiber core, optical fiber cladding, monitoring protection and outer protection.

Basic structure of laser cable

Laser cables are mainly classified by parameters such as fiber core diameter, cable length, and cable connector type. At present, the market is mainly divided into two types of optical cable according to the optical cable connector: QHB type connector mainly based on fiber laser and LLK type optical cable connector based on TRUMPF laser. The LLK laser fiber optic cable launched by TRUMPF Laser is widely used in TRUMPF disc lasers, semiconductor lasers, fiber lasers and pulse lasers. Compared with QBH optical cable, LLK optical cable has the characteristics of low failure rate and plug and play.

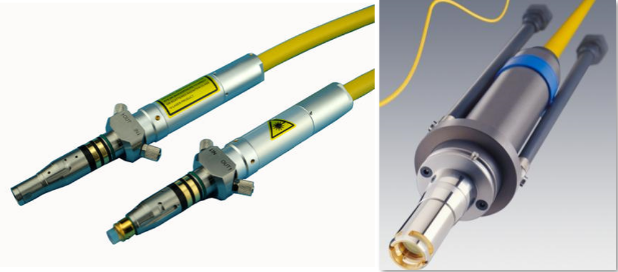

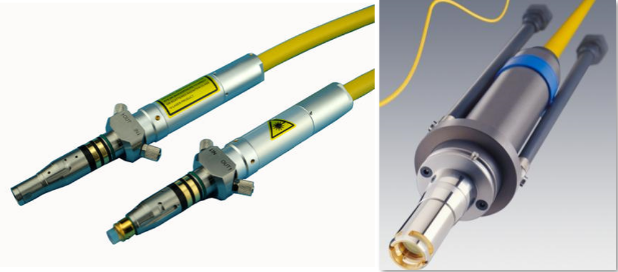

Comparison of appearance of QBH type (left) and LLK-D type (right) optical cables

Low failure rate

The high stability of the optical cable can better ensure the normal operation of the equipment and reduce maintenance time and costs. The LLK type optical fiber cable with multi-layer protection measures can greatly reduce the fiber failure rate. Through the analysis of the equipment installed and used by customers in recent years, the failure rate of the LLK type fiber is only 1%. Compared with the QBH type fiber, the failure rate is Is very low.

Quick plug

In order to reduce costs, fiber lasers mostly use fusion splicing to connect QBH optical cables and laser light sources. This can realize the integrated structure design, but it has greater drawbacks when replacing new applications and troubleshooting, requiring specialized maintenance personnel and equipment to replace the optical cable. Long replacement process time is also a problem.

During process development or production line transformation, the original optical cable may no longer meet the new process requirements. At this time, the easiest method is to modify the original equipment. Transformation by replacing the laser optical cable is an efficient way. TRUMPF optical cable supports optical fiber plug and play. Take the disk laser of TruDisk 6001 as an example. Replace the 100-micron fiber optic cable used for cutting with a 200-micron fiber optic cable with a suitable welding processing head, and it can be directly used for laser welding testing or production.

And when the equipment is shut down due to fiber optic cable failure during production, the plug and play of the fiber optic cable can resume production at the fastest speed. Since the LLK optical cable supports both ends plugging and unplugging, a hexagon socket screw tool can be quickly replaced. The entire replacement time can be completed in only a few minutes. Compared with the QBH splicing fiber optic cable that takes about half a day, the LLK fiber optic cable reduces downtime and improves production efficiency.

Good flexibility

TRUMPF provides a variety of LLK optical cables to meet a variety of process requirements. In terms of optical fiber structure, TRUMPF Laser can provide a single-core optical cable with only one transmission fiber, or a two-in-one dual-core optical cable that is widely used in solving welding spatter. Dual-core optical cables were originally used for efficient cutting of medium and thick plate materials on TRUMPF machine tools, which can quickly perform piercing (drilling) and cutting. In addition, square and rectangular optical cables are also a standard product for laser cleaning, de-plating and other surface treatments.

High security

The fast plugging and unplugging of the optical cable can achieve maximum flexibility, in order to further ensure the accuracy and safety of the connected optical cable. Each optical cable integrates a chip that records the information of the optical cable, and the information of the chip can be directly read by the laser, which protects against poor contact and misplugging.

In addition, when the laser performs multi-optical switching production, the laser and the laser optical cable together form an intelligent laser network. Encode the laser and the output optical path through the laser network. If the parameters called by the upper computer control system (robot or upper computer PLC) do not match the actual connected hardware, the laser will give corresponding alarms to avoid light emitting errors.

In short, the laser fiber optic cable is an important part of the laser industrial production system. The low failure rate, safety and quick replacement of TRUMPF laser optical cables can achieve the highest production efficiency and are fully prepared for future intelligent manufacturing.

View More(Total0)Comment Lists