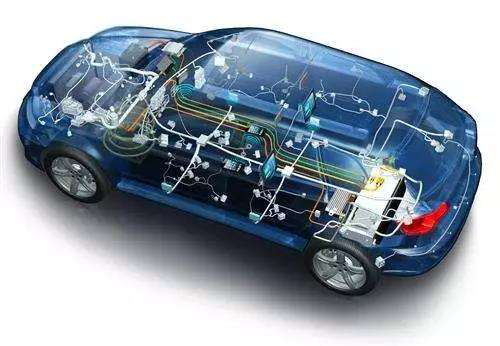

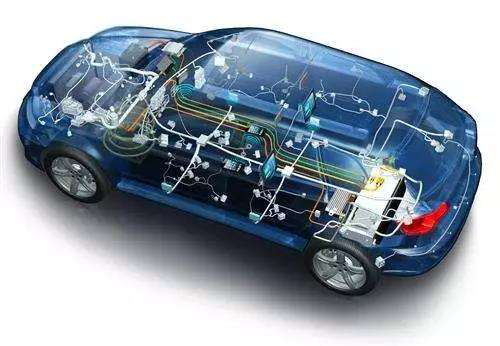

When we sit in the car and can easily control the windows, air conditioners and even the steering wheel, we may not imagine that the electrical distribution system hidden under the car shell is transmitting signals between the wiring harnesses of thousands of kilometers. With the advent of a new era of mobile mobility, more active safety functions, infotainment systems, and network interconnection services have emerged in smart vehicles, which has made the electrical architecture inside the car extremely complex.

In 2019, the night before the arrival of self-driving cars, a car needs to transmit enough 15,000 pieces of data in a blink of an eye. At the same time, many new sensors and radars need to consume a lot of energy. From 1995 to 2005, car energy consumption almost doubled, from 700 watts to 1100 watts. At present, the energy consumption of automobiles can reach 40,000 watts, which is equivalent to the energy consumption of a house, and the number of automobile wiring harness circuits has reached 3,200.

Historically, when a car adds new features (such as heated seats), it is only necessary to add a new control module and wiring. Then in the L3 and L4 automatic driving systems, an unoptimized system needs to add nearly two kilometers of wiring. 5 kilometers of wiring harnesses and connectors installed in today's cars is a great challenge to the trend of lightweight and electrified cars.

Rethinking vehicle architecture

What kind of electrical architecture does the car of the future require? How is the electrical distribution system of smart vehicles evolving? With these questions in mind, we visited the Tianjin wire harness production base of the world's leading technology company Apollo, and Mr. William T. Presley, the global president of Apollo's electrical distribution system, and the vice president of Asia Pacific. Mr. Anu Rathninde, Managing Director, also conducted in-depth exchanges on issues such as the evolution of automotive electrical architecture.

Picture Source 360 Website

Presley mentioned that "the future of automotive architectures will have three S: one is simplified, one is scalable, and one is sustainable. Today's automotive architecture systems have a very large centralized power distribution center, and a distributed computing system. What Aberfoss has to do is turn it into an integrated central computing system, while the power distribution system is distributed, so that it can use these existing modules in some vehicles to reduce the size and weight of the electrical distribution center, which can reduce emissions and increase the mileage of the car. "

In the past few decades, automobiles have been providing increasing features and functions by using the knowledge of computing platforms . The advent of high-performance computing platforms has naturally integrated automotive functions. The car of the future will transform into a software-defined platform. Aiming at the feature-rich and highly automated vehicles, Apollo proposed a sustainable and optimized intelligent vehicle architecture (SVA) topology, which includes a power data center (PDC), a data backbone network, and a central computing cluster for processing a overall solution of calculations signal and power transmission, helping support software-based functions, fast data transmission, and meeting the redundancy requirements of the highest level of automotive safety, ensuring that the car can still run safely after a breakdown, and can also meet the industry's most stringent operational security and cybersecurity standards.

Presley believes that "every OEM and every vehicle architecture in today's automotive architecture is different, and smart vehicle architecture (SVA) is to enable you to have some basic parts, such as power data centers, and central computing. In a cluster, such a block can be placed on any vehicle. The only thing to change is the length of the electrical distribution system. Therefore, each vehicle does not need to have a separate architecture. All vehicles have the same architecture. This is achieved through solutions and software applications. So it is no longer necessary to customize every architecture. "

Automotive wiring harness patterns under new trends

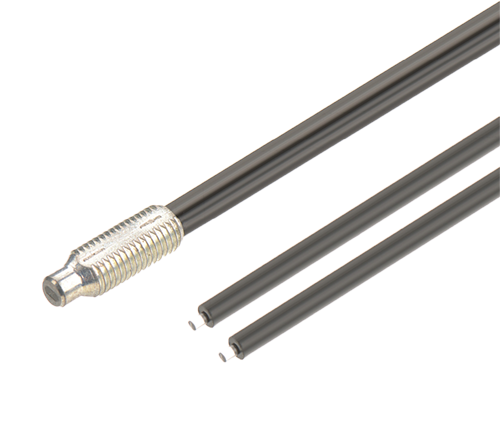

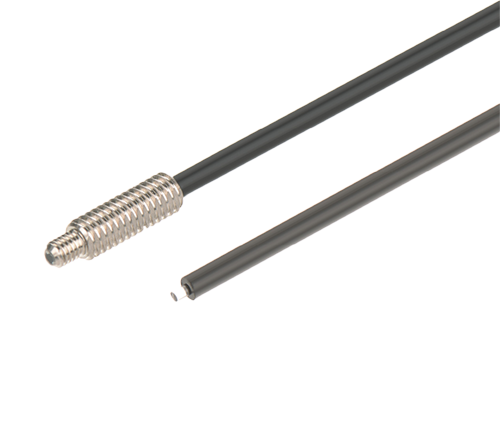

Automobile wiring harness is the main body of the network of automobile circuit. Without wiring harness, there is no automobile circuit. The longer the wire harness, the larger the volume, which will increase the weight of the vehicle, and the increase in weight often means that the mileage of electric vehicles will decrease. With electrification, automotive wiring harnesses have also evolved. The wiring harness in the automotive electrical distribution system is a core component of Apollo's intelligent vehicle architecture.

In terms of light weight, some materials, science and technology can be used to reduce the weight of materials. For example, some high-voltage wiring harnesses were previously made of copper, and now they can be made of aluminum. There is also miniaturization, such as using some alloy technology or other technologies, which can increase the wiring density in future vehicles, so that these wiring harnesses can be accommodated without increasing the volume of the vehicle. Some wiring harness circuits are too small or too thin for manual operation to complete, so the entire manufacturing process must be changed.

Challenge of Intellectualized Remodeling

In 2020, more ADAS, infotainment, and user experience functions will appear in automobiles. As a leading global wire harness manufacturer, it will also face many key challenges: in terms of development, the increase in complexity and interdependence will make the timeline extend; in terms of manufacturing, the vehicle faces problems of insufficient physical space and assembly difficulties; in terms of post-production, engineering maintenance brings a heavy burden and cannot enhance functionality.

Picture Source 360 Website

Although there are many problems to be solved in the future, I believe that when Delphi becomes Ambofo, Ambofo is ready and has its own clear positioning: to provide the 'brain' and 'nervous system' needed for future cars so that mobile travel can become more secure, green and connected.

JYFT provides good quality of plastic fiber optic cable, plastic fiber optic cable connectors, plastic fiber cable, if you want to buy our product, please contact us.

Related Products

Related Products

View More(Total0)Comment Lists